Lesson #3: Moisture content hidden by broken kernels

At the beginning of the drying season, we observed this phenomenon. This led to a rather interesting observation: the effect of moisture dilution by the mass of broken grain.

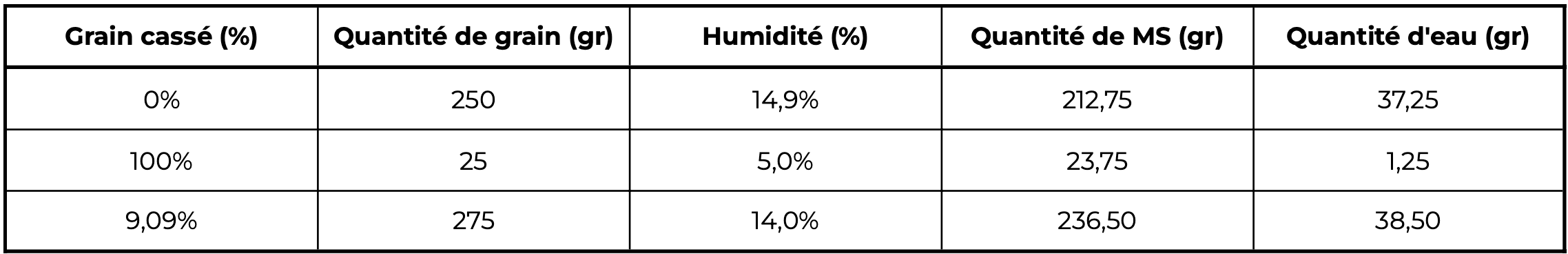

Since broken grain is smaller, it is obviously drier. So let's say your sample contains 10% broken grain, its moisture content is 5.3%, and your grain's moisture content is 14.9%. In reality, your test result will be 14.0%*. This is simply because the amount of broken grains will mask the actual moisture content of your grain.

250 grams of grain x 14.9% -> 37.25% water

275 grams of grain x 14% -> 38.5% water

Table showing moisture content results for whole grain, broken grain, and combined grain.

Of course, the exceptional effect of having such a high percentage of broken kernels (around 10%) made it possible to observe this phenomenon. However, after repeating the experiment throughout the season, we observed a significant influence, generally 0.5%, of broken kernels on grain moisture measurements.

Why is this so important?

As you know, broken grain will concentrate in the center of your silo. Once the center of the bin is removed, you will be left with nice round grain, with a much lower loss rate. It is not uncommon to have a rate of 7-10% at the beginning of the bin emptying process, then 2-4% for the rest of the bin.

So if you don't pay attention to this, you may end up with grain that is slightly more moist than expected. Stay alert!

Discover the 5 lessons learned from the 2025 harvest.

[1]Simplified calculation to present the observation made at harvest.